Back to Blog Page

Web-to-Pack Solution for Personalized Packaging: A Detailed Guide

Summary: Struggling to meet the changing customer demands of your print packaging business? Modern packaging technologies like web-to-print solutions can help printers to address the day-to-day printing challenges and deliver extraordinary customer experiences. This blog will cover all the necessary information to help you adopt this web-to-pack solution and stay competitive in the evolving print landscape.

A few years ago, packaging was simply meant to cover the product. But times have changed. Printers have identified that it is possible to get recurring orders from customers just by providing a personalized unboxing experience.

Slowly, customers started liking personalized packages with custom names and messages in it, providing a unique experience that makes them buy more from the brand. Think about the unboxing videos you see on social media, it's the packaging that catches the attention more than the product.

Not only that, the personalized packaging market is anticipated to rise from USD 41.0 billion in 2025 to USD 77.7 billion by 2035 at a CAGR of 6.6% from 2025 to 2035.

This demand for personalized packages let to the increased need for a robust innovation like advanced web-to-pack solution which we will be talking about in this comprehensive blog.

From basics of web-to-pack to popular trends for winning more business, this blog will provide you with valuable insights into this solution for personalized packaging.

So, without further ado, let’s dive into the blog.

On This Page

- What is Web to Pack?

- What is Web-to-Pack Solution?

- Why Print Business Need Web-to-Pack Solution Now?

- How Web to Pack Technology Works?

- Key Features to Look for in Web to Pack Solutions

- How to Choose the Right Web to Print Packaging Solution

- Steps to Implementing Web to Pack Solution

- Benefits of Implementing Web to Pack Solutions

- Packaging Industry Trends That Web-to-Pack Solutions Can Address

- Wrapping It Up!

What is Web to Pack?

Web-to-pack is nothing but the adaptation of web-to-print technology by the packaging industry. It allows customers to order packaging products like boxes and cartons via a web-based storefront.

In simple terms, it is the concept or process of ordering packaging via an online platform.

What is Web-to-Pack Solution?

A web-to-pack solution is an innovation that enables web-to-pack. It's the actual solution used by print packaging providers to offer everything ranging from the storefront, design personalization tools, order management to integration capabilities.

In essence, it's a solution that enables printers to offer web-to-pack.

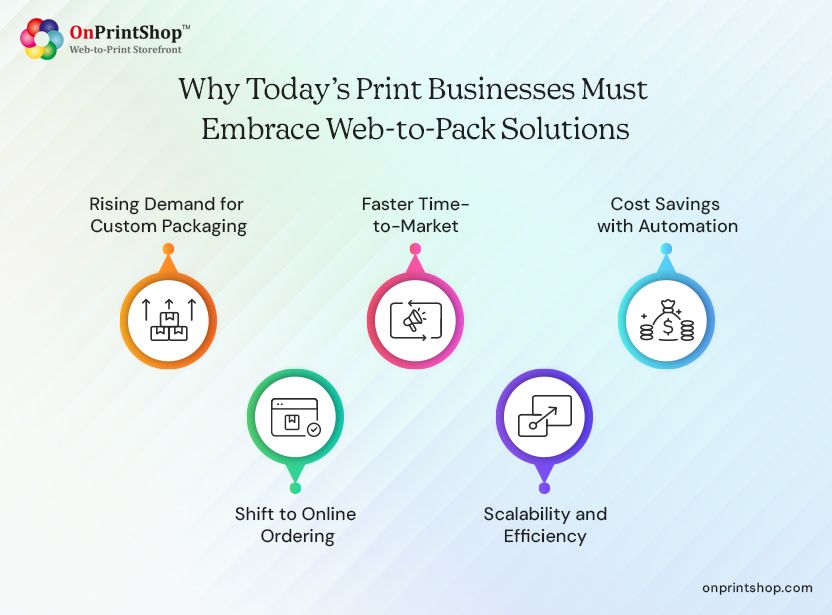

Why Print Business Need Web-to-Pack Solution Now?

Since the customer demands have changed over time and a powerful system is required to meet these evolving needs, print businesses need a web to print packaging solution in today’s world. Let’s see in detail why this personalized packaging software has become a necessity and what problem it solves.

1. Rising Demand for Custom Packaging

With more customers wanting personalized unboxing experiences, the demand for custom packaging has increased.

2. Shift to Online Ordering

Due to the convenience of online ordering, people prefer this method over walk-in purchases, email, or phone calls.

3. Faster Time-to-Market

The faster time-to-market has become necessary because customers expect quick delivery and easy print ordering options.

4. Scalability and Efficiency

As packaging print businesses grow, a robust system is required to handle the increased order volumes and changing demands.

5. Cost Savings with Automation

An automation-based system can save costs by reducing manual labor, errors, saving time, and streamlining workflows.

How Web to Pack Technology Works?

The Web-to-Pack technology works by allowing customers to place packaging orders online, which are then sent for production and delivered to their doorstep. Let’s understand the steps involved in this entire journey, right from order placement to delivery.

1. Browse & Personalize Packaging

In this stage, the customer browses the different packaging products from the web-to-print storefront and personalizes it as per requirements.

2. 3D Visualization & Proofs

Next, the customer visualizes the packaging product in 3D format and proofs the design by collaborating with the designer and team members.

3. Pre-Press Checks & Optimization

When the order has been pushed to the pre-press stage, it goes through file review and validation, color management, layout & imposition, and creates ready-to-print files.

4. Production to Finishing

After production, it goes through post-press operations like cutting, folding and binding as well as finishing processes like design embossing, die-cutting, varnishing and laminating.

5. Shipping & Tracking

This stage involves the process of carefully packing the orders and adding labels to each of them for effective shipping and tracking.

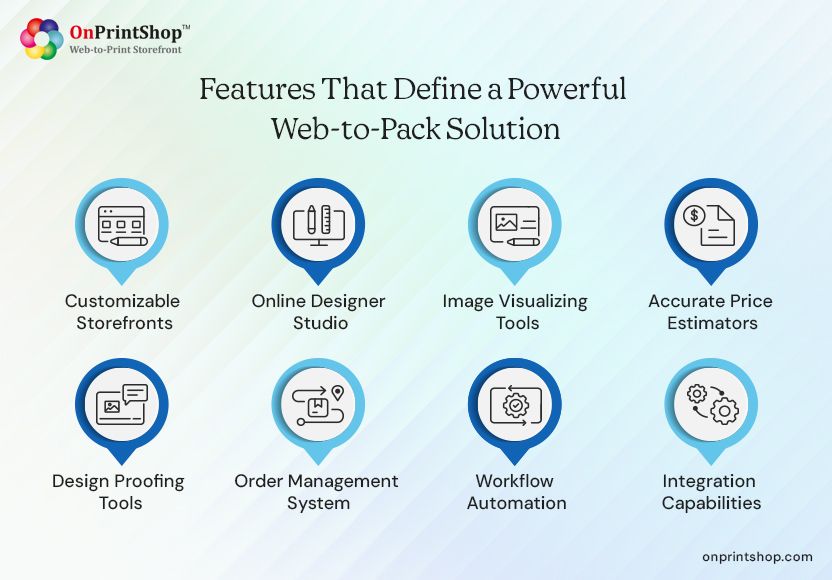

Key Features to Look for in Web-to-Pack Solutions

Since every print packaging business is different, the features required in a web2pack solution will also vary. However, the essential features that are a must look for in this packaging innovation are given below.

1. Customizable Storefronts

Ensure the web to print packaging solution offers customizable storefronts for B2B and B2C businesses. The storefront should be intuitive, user-friendly, offer multi-store management, and easy-to-use on various devices including mobile phones and tablets.

2. Online Designer Studio

Find an intelligent 3D packaging design software with a web-to-pack focus that offers an AI-powered designer studio to create stunning packaging designs instantly. Look for tools that support the creation of eye-catching packages like corrugated boxes and bubble wraps via pre-designed templates and easy-to-use design options.

3. Image Visualizing Tools

The 3D preview of the design will look like a virtual mockup where customers can view, rotate, and zoom. Having the capability to visualize the packaging designs in 3D format can help your customers enhance their decision-making capability in placing orders.

4. Accurate Price Estimators

Ensure the web to print packaging solution enables your customers to see an accurate estimation of the final order. Along with that, ensure it offers a complete breakdown of the costs such as additional amount added for advanced finishes or fast shipment.

5. Design Proofing Tools

Make sure the online packaging with web to pack solution offers cutting-edge design proofing tools with transparent approval workflows. Capabilities like version control for designs, seamless collaboration between designers and customers, and system generated emails are a must-have in a packaging solution for printers.

6. Order Management System

Find a web-to-pack innovation offering advanced order management software that is built specifically for print packaging providers. Look for capabilities like automated order processing, inventory management, multi-channel order management, and more.

7. Workflow Automation

Check if the solution offers workflow automation capabilities that streamlines processes from order intake to packaging to delivery. With a centralized view of the print operations, this feature will allow you smoothly run your packaging business.

8. Integration Capabilities

Ensure it seamlessly connects with existing workflows and supports advanced W2P integrations with third-party tools such as CRM, MIS, ERP, accounting, shipping, marketing, and more. Check if it also supports integration with shipping providers like FedEx, UPS, DHL and Ecom Express.

How to Choose the Right Web to Print Packaging Solution

As a print packaging provider, choosing the right web-to-pack solution can be one of the most important decision and hence careful consideration needs to be made for the same. Let’s discuss a simple step-by step approach to help you get started.

1. Map Your Existing Packaging Workflow

Evaluate your existing print packaging workflow from order placement to delivery. Identify the pain points and inefficiencies that need to be addressed as well as your budget constraints. This will help you in finding the right web-to-pack software that suits your unique business needs.

2. Shortlist Online Packaging Solution Providers

Create a solution provider checklist to compare different options and make the right decision for your print packaging business. Find which web-to-pack provider can help you overcome your packaging challenges using web-to-print tech by identifying your required features, maximum budget, and scalability options.

3. Request a Detailed Demonstration

After shortlisting the solution provider, request a detailed demonstration of the solution capabilities. By understanding how the web to pack software works in the real-world and enquiring how it can help you tackle your print packaging inefficiencies, you can make an informed decision for your business.

Steps to Implementing Web to Pack Solution

If you have selected the packaging solution for printers, next think about how you can successfully implement it. While the implementation process can be quite straightforward, it's important to keep certain things in mind before beginning.

1. Define Implementation Goals

Set clear objectives such as what you want to achieve by implementing this solution. Whether you want to reduce manual order handling in packaging workflows, handle complex packaging requirements like bulk corporate orders or multi-SKU.

2. Train Staff and Stakeholders

Next, train your teams in the sales, pre-press, production, and customer service operations to effectively use this newly implemented system. Provide them with the essential knowledge-building resources such as help documentations and tutorials.

3. Test Integration With Your Systems

Check if the web to pack platform integrates with your existing systems and other third-party applications. You can try running a mock order from order placement to delivery to check if the data flows seamlessly and workflows operates effortlessly.

4. Make a Pilot Run of the Test

After shortlisting the solution provider, don’t immediately move to a full-scale implementation. Test the solution of web to pack for packaging industry in a controlled pilot run to see how it's performing in the real-world, check if it is providing measurable improvement in print packaging operations.

5. Monitor and Optimize

Use leading-edge reporting and analytics tools to measure important performance metrics and check if the new system works appropriately. Collect feedback from both internal team members and customers to know if the processes have improved and where it can be optimized.

6. Full Rollout of the Solution

After the pilot run and understanding the performance metrics you can fully implement the solution and expand it gradually. Add new packaging products to your storefront by leveraging integrations and serve multiple locations as a part of your scalability plan.

Benefits of Implementing Web to Pack Solutions

Adopting an online packaging with web to pack solution can not only benefit printers but also customers in several ways. Let’s have a look at how the innovative capabilities in this solution help each of them.

1. Significant Benefits for Print Packaging Businesses

Modern print packaging providers can significantly benefit by utilizing web-to-pack solution in the following ways.

More Efficiency and Less Errors in Packaging Orders

This automation-driven solution eliminates repetitive tasks like order processing to reduce manual errors and increase operational efficiency. It streamlines collaboration across team members and provides version control to keep track of design iterations, avoiding miscommunication and human errors.

Cost Savings through Automation-Centric Operations

These solutions automate the pre-press, production, and post-press operations, reducing material wastage and eliminating rework. This reduces the extensive usage of raw materials, leading to cost savings and controlled budgeting.

Enhanced Customer Satisfaction with Personalized Packaging

The web to pack technology based solution enables print packaging businesses with the capability to provide their clients with the capability to tailor packages as per their branding requirements. It enables the production of high-quality packages and timely order delivery, ensuring enhanced brand reputation and high customer satisfaction.

2. Significant Benefits for End Customers

Let’s see the customer-facing benefits of implementing a web-to-pack solution.

Intuitive Storefront with Ready-to-Use Design Tools

The solution offers a user-friendly storefront with an intuitive interface for customers to browse and quickly create eye-catching packaging designs, irrespective of their design skill level whether beginner or professional.

It provides customers the flexibility to upload files or choose from various pre-designed templates for design creations, providing a 3D visualization of the final design in real-time and options for swift approvals.

Fast Delivery Without Compromising Quality

The automation-focused solution speeds up the entire print order cycle and integrates with shipping providers to ensure faster delivery of the packaging products and in high quality.

Customers can choose their desired delivery time frame such as 5-7 business days or 10-12 business days and benefit from order tracking, resulting in on-time delivery and enhanced satisfaction.

High-Quality and Customized Packaging

Clients can choose the specifications for their packaging ranging from dimensions, material type to quantity, ensuring that the final product meets their exact requirements.

The solution delivers high-quality and customized packaging to clients, providing memorable packaging with enhanced brand recognition.

Packaging Industry Trends That Web-to-Pack Solutions Can Address

Several in the packaging industry are gaining traction nowadays. Adopting these trends will not only help you serve your customers better but gain more profits. Let’s quickly see these trends and how a web-to-print solution can address them.

1. Demand for Personalized Packages

Modern customers prefer personalized packaging with unique names, logo, and messages, that provides a special unboxing experience.

By utilizing a packaging design software backend by web-to-pack technology, you can get online design tools, pre-designed templates, and variable data printing capabilities for delivering unique packages.

2. Growing Demand for Short-Run Packaging

Factors like e-commerce and D2C growth, costs and storage pressure due to overproduction, the short-run packaging trend has a huge demand.

By offering automated ordering, cost-effective short runs, and faster time-to-market, web-pack platform effortlessly solve this trend.

3. Sustainable and Eco-Friendly Packaging

Due to global environmental concerns, customers and printers are choosing sustainable packaging as well as opting for brands that utilize eco-friendly practices for producing them.

Modern web to pack software addresses this trend by offering digital proofing methods, reports & analytics that help in making sustainable decisions like reducing waste & optimizing resources and allowing print-on-demand model.

4. Smart Packaging with QR Code Integration

As the smart packaging market is booming, the trend of adding QR codes on packages for product traceability and information sharing is on the rise.

Web to pack technology enables the creation of eye-catching QR codes with branded colors, logos, and styles in the packaging products.

Wrapping It Up!The adoption of web to pack platform is not just optional – its a necessity for print packaging providers. Simply adopting this solution will not be enough but staying updated with the latest trends will help you stay competitive and maximize profits.Furthermore, opting for a new-age web-to-pack solution like the ones provided by OnPrintShop, print packaging providers can automate workflows, deliver personalized experiences, and increase revenue. If you haven’t explored the top-notch capabilities of OnPrintShop’s web-to-pack solution yet, then request a demo and our team will get in touch with you. Don’t just keep up, lead the way in packaging by connecting with us today!

FAQ's

Does web-to-pack support B2B brand portals for multi-user teams?

Can web-to-pack handle complex packaging SKUs with multiple components?

How do shipping and logistics work with web-to-pack orders?

Can I set different storefronts for different client segments?

#1 Web to Print Software.

By submitting this form, you agree to our Privacy Policy