Back to Blog Page

How to Make a Repeating Pattern Designs for Print

Blog Summary: What’s the easiest way to make your products stand out? Pattern print is the answer. Repeating pattern design helps print businesses automate personalization, expand product catalogs, and enhance customer experience. Learn how Web-to-Print users can create, apply, and profit from seamless repeat patterns.

Repeating patterns are everywhere, from product packaging and clothing to wall decor, accessories, and branded corporate merchandise. What once required traditional textile design expertise can now be created, scaled, and customized with ease inside modern pattern design software.

As consumer expectations shift toward more personalized products, repeat pattern design empowers businesses to deliver visually rich results without manual effort on every order.

For print service providers, the transition from static designs to dynamic pattern-based personalization presents both creative and commercial opportunities. With a single tile, businesses can unlock hundreds of product variations while customers enjoy real-time previews and intuitive customization experiences. Whether it’s a subtle step-and-repeat background or a bold branding-heavy logo grid, repeating patterns help elevate aesthetic appeal while streamlining production.

In this blog, we break down the pattern types, design workflow, print best practices, and revenue opportunities, helping Web-to-Print users confidently turn patterns into profit.

On This Page

- What Is Repeat Pattern Design and Why It Matters for Modern Web-to-Print Users?

- Popular Pattern Types Used Across Print Products

- Step-by-Step Process: How to Make a Repeating Pattern Designs for Print

- Designing Repeating Patterns Inside Your Web-to-Print System

- Best Practices for High-Quality Pattern Printing

- How W2P Businesses Can Profit from Repeating Pattern Designs

- Conclusion

What Is Repeat Pattern Design and Why It Matters for Modern Web-to-Print Users?

A repeating pattern design is made of elements, logos, or designs arranged in a way that allows them to tile seamlessly across a surface. When repeated continuously, it creates the illusion of a single unified design. While repeat patterns have existed for centuries in textile repeat design, tiles, and decorative art, their significance has grown dramatically in digital-first printing environments.

For print service providers, the importance of repeating patterns goes far beyond aesthetics. Pattern-based designs make it possible to streamline personalization, enabling customers to create visually impactful products without needing advanced design knowledge.

Once uploaded, a repeat pattern can appear instantly on wallpapers, food wrapping papers, gift wrapping materials, curtains, bedsheets, mugs, phone cases, photobook covers, boxes, posters, and many other products through automated product previews. More importantly, pattern libraries allow print businesses to expand their online pattern design catalog without creating individual designs for each product.

This makes the print pattern design both a visual asset and a high-efficiency workflow tool that increases conversions, simplifies ordering, and reduces design workload across the business.

However, to automate and streamline this process is a challenge of its own. And that’s why pattern design software has played an important role in the textile industry.

Popular Pattern Types Used Across Print Products

Repeating patterns may look simple on the surface, but the way a tile repeats dramatically influences the final appearance of the printed product. In Web-to-Print environments, this becomes even more important because patterns need to scale and adapt across multiple product sizes, like business cards, gift wraps, labels, packaging sleeves, tote bags, signs, or textile repeat patterns, without needing manual repositioning. Understanding the common types of repeats helps designers and print business owners choose patterns that not only look good up close but also maintain rhythm, balance, and visual appeal across large and small surfaces.

Below are the most widely used repeat styles seen in commercial print products, each with its own visual character and best-use scenario.

Full Drop

The full drop style repeats identically across both horizontal and vertical axes, similar to floor tiles. It is the most traditional and predictable type of pattern repeat. Because it is simple and uniform, full drop is easy to produce and ideal for structured designs such as geometric prints, corporate branding patterns, monograms, or backgrounds that must remain stable and consistent.

When used in Web-to-Print systems, full drop works exceptionally well because it scales cleanly, requires minimal alignment checking, and previews beautifully on products of varying dimensions. Many businesses prefer this method because it guarantees visual consistency when printed on large continuous surfaces like wallpaper panels, packaging sheets, or wide-format display rolls.

Half Drop

The half drop repeat introduces a more dynamic and flowing layout by staggering every alternate row by half the tile width. The result is a visually richer composition that breaks the rigid grid-like look of a full drop, making it popular for artistic patterns, floral motifs, abstract surfaces, and nature-inspired repetitive design patterns.

The staggered arrangement helps hide repeat lines and creates a more organic flow that appears less mechanical, particularly when printed on large areas. In print, half drop repeats are commonly used in wrapping papers, apparel, upholstery, textile accessories, and decorative packaging, where a sense of movement adds personality to the product.

Brick

A brick repeat pattern design is similar to a half drop, but instead of shifting rows vertically, the shift happens horizontally at a controlled offset, often a third or half of the tile height. This pattern resembles the layout of bricks in a wall, hence the name. Brick repeats are extremely effective when the design elements benefit from horizontal rhythm, such as stripes, icon grids, or motifs that form ladder-like or wave-like flows.

Print buyers appreciate brick repeats for their versatility: they feel structured yet visually interesting, and they adapt well to products that will be viewed from a distance, such as banners, signage, textile repeat design, or large packaging formats.

Mirror

Mirror repeats flip the tile along vertical or horizontal axes, creating symmetrical reflections of the original artwork. This technique is especially powerful for designs based on natural brushes, watercolor textures, ink strokes, feathers, leaves, or any motif where organic imperfections create beauty.

Mirroring allows designers to get maximum visual impact from minimal original artwork, two or four visual variations from one tile. This makes it both time-efficient and print-friendly. In Web-to-Print storefronts, mirror patterns are highly valued because they generate intricate-looking designs that still repeat seamlessly, helping businesses deliver premium-looking products with limited design effort.

No Repeat

No repeat doesn’t technically replicate the pattern beyond its tile; it is a single design element used as-is across the product. This style is often used when the focus is on a hero graphic, brand logo, or singular composition that benefits from open space. In packaging, signage, or premium stationery, this approach helps maintain brand dominance and visual clarity.

While not a repeating pattern by definition, “no repeat” is important in W2P product logic because many storefronts allow customers to switch between full-bleed patterns and centered artwork layouts. For example, a gift box may feature a single illustrative center pattern on the lid, while the rest remains clean and minimal. This option ensures design flexibility across different print product categories.

Step and Repeat

Step and repeat is one of the most recognizable pattern types in commercial printing, especially in branding-heavy applications. In this layout, a logo or small motif is repeated evenly across the surface, often with consistent spacing and alignment. Think red carpet backdrops with brand logos, promotional event walls, uniform gift wrap branding, or corporate packaging.

This pattern style reinforces visual identity while maintaining clean, structured repetition. In Web-to-Print workflows, step and repeat layouts are especially effective because customers can upload their logo and see instant previews on banners, boxes, tissue paper, or other printed merchandise, reducing manual design involvement and speeding up order fulfillment.

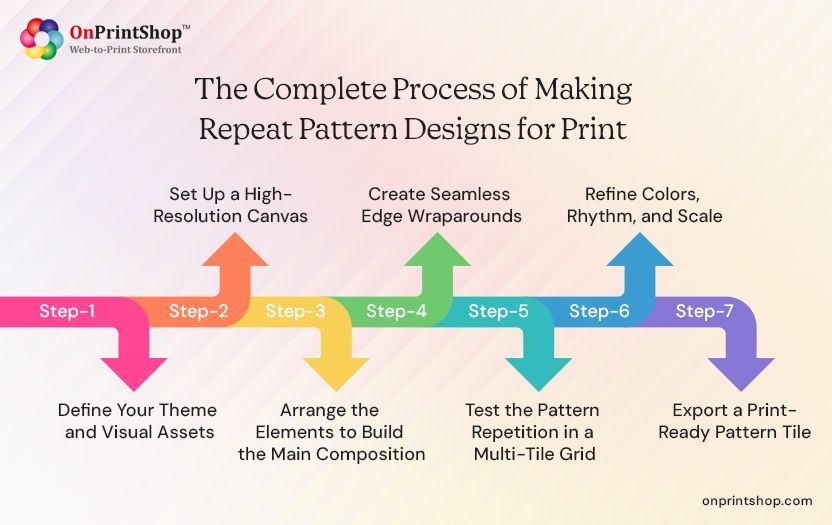

Step-by-Step Process: How to Make a Repeating Pattern Designs for Print

Designing a repeat pattern requires creative skill, visual balance, and a thoughtful production process. Below is a practical workflow used by professional designers and Web-to-Print studios.

Step 1: Define Your Theme and Visual Assets

Every great pattern begins with a focused direction. Designers first select the key elements that will appear in the repeat, illustrations, icons, shapes, textures, or brand motifs. At this stage, it is helpful to determine whether the pattern should be playful, elegant, bold, minimal, or seasonal, as this informs the style of the artwork and its intended audience.

Many designers sketch or build multiple exploratory variations before committing to the final set of visual elements that form the foundation of the pattern tile.

Step 2: Set Up a High-Resolution Canvas

Before placing any elements, the designer creates the tile itself. For print, a tile measured between 1000 and 4000 pixels (or 10–30 cm) at 300 DPI is generally appropriate. Working directly in CMYK ensures consistent color reproduction across different printing methods.

This tile will become the building block of the full pattern, so correct sizing and setup at this stage avoids costly rework later in the production process.

Step 3: Arrange the Elements to Build the Main Composition

Once the canvas is ready, designers begin arranging motifs inside the tile. The goal is to achieve visual balance. Ensure the eye travels smoothly across the design without any one area feeling overly dense or empty.

The arrangement should also reflect the planned repeat style, whether straight grid, half-drop, or brick-based layout. Designers take care not to crowd elements too tightly, as repeating tiles often exaggerate such spacing issues once multiplied across larger surfaces.

Step 4: Create Seamless Edge Wraparounds

Achieving continuity is the true challenge of seamless pattern designs. Any motif that crosses one edge of the tile must appear in the exact corresponding position on the opposite side.

For example, an illustration touching the left edge must also reappear at the same vertical position on the right. Repeat pattern software with the right features can automate this process, but traditionally, designers manually copy and shift elements to keep placement mathematically accurate. If this step is done well, the tile will join itself in all directions without visible seams.

Step 5: Test the Pattern Repetition in a Multi-Tile Grid

No pattern should be approved without proper testing. Designers duplicate the tile into a grid, often 2x2, 3x3, or larger, and view it zoomed out to ensure that no seams, visual gaps, awkward clusters, or unintentional focal points appear. Sometimes a single small imbalance becomes obvious only when repeated hundreds of times across a surface.

This refinement stage often involves subtle movement of shapes, resizing motifs, or adjusting spacing to ensure that the final pattern feels harmonious and natural. This step can be made a lot easier with the intuitive online designer studio offered by the advanced repeating pattern software, as it allows you to preview your design in real time.

Step 6: Refine Colors, Rhythm, and Scale

Once the structure holds together, designers refine color palettes and spacing. Certain products, such as packaging or signage, demand higher contrast and bold shapes, while stationery and wedding items often benefit from softer tones and more measured spacing.

At this stage, designers also test the different patterns like step and repeat, full drop, and half drop, at different scales, to ensure that it works equally well on small merchandise like keychains and large surfaces such as banners or fabric yardage.

Step 7: Export a Print-Ready Pattern Tile

With the final tile ready and tested, designers export the file in print-ready format. PDF, TIFF, and PNG are commonly used, depending on the printing method and W2P system. At this stage, designers ensure that file resolution, color mode, and bleed settings follow production standards.

Once exported, the tile can now be uploaded to a Web-to-Print storefront, where customers can preview the pattern live, adjust scaling, apply it across multiple products, and generate print-ready outputs automatically.

Designing Repeating Patterns Inside Your Web-to-Print System

A modern Web-to-Print system allows pattern design, visualization, and final production setup to happen in one place, with the built-in repeating pattern software. Instead of creating repeat patterns offline and uploading files repeatedly, users can design directly in the browser, apply elements, and adjust tile size instantly on real products.

This matters because repeating patterns behave differently at different scales, and the ability to preview them in real time helps avoid misalignment, overcrowding, or empty space before an order is placed.

Once finalized, the system automatically generates print-ready output with the right bleed, resolution, and color settings. This eliminates the risk of incorrect files and ensures consistency across multiple product types, whether the same pattern is used on packaging, stationery, merchandise, or signage.

The biggest shift is that customers can now personalize patterns themselves, uploading a logo, tweaking layouts, or selecting variations, without waiting on a designer. This reduces turnaround time, cuts down on repetitive design tasks, and turns pattern-based product lines into a scalable, self-serve revenue stream.

Best Practices for High-Quality Pattern Printing

Even the best pattern can fall short if print execution isn’t handled correctly. Here’s how to ensure your final output always looks flawless.

Maintain High Resolution Without Unnecessary File Weight

A repeat pattern must remain sharp at all print sizes, whether it appears on small business cards or large packaging. This is why creating repeating patterns at 300 DPI or higher is recommended by experts.

However, it’s equally important to avoid bloated files that slow down ordering and production systems. Vector artwork is ideal when possible since it remains crisp at any size without increasing file size. When raster textures are needed, designers should crop and compress efficiently, keeping master tiles high quality and final files production-friendly.

Ensure Seamless Tile Alignment for Continuity

Nothing breaks the illusion of a repeating pattern faster than visible seams. Designers must zoom in carefully and test tiles at various scales to ensure elements align perfectly on all four edges. A useful technique is to preview the tile applied across a larger canvas. This makes vertical and horizontal mismatches easy to spot.

Once corrected, designers should preview how the pattern behaves with different product dimensions because unusual sizes may expose visual imbalances or crowding. A well-prepared tile should work consistently across all placements without manual adjustment

Prepare for Variations in Print Substrates

Different materials absorb ink differently, and this affects how colors appear. A vibrant pattern printed on coated paper might look subdued on fabric, canvas, or kraft packaging. Designers working for print output must understand how color translates across substrates.

This often means adjusting curves, compensating saturation, or generating alternate color profiles when targeting multiple product ranges. Testing is key. A pattern intended for multiple surfaces should be proofed or simulated before mass production begins.

Use Bleed and Safe Margins for Edge-to-Edge Printing

When patterns reach the edge of a product, such as packaging or signage, bleed helps ensure no accidental white edges appear due to trimming. Designers must extend patterns beyond the final cut line, giving production equipment adequate tolerance during finishing.

Similarly, elements that must remain fully visible should sit within the safe margin. While repeat patterns often continue infinitely, this practice prevents misalignment or unexpected clipping if the customer orders variations in dimension.

Stay Consistent in Color Mode and Output Format

For digital displays, RGB works beautifully. For print, it doesn’t. Every production-ready pattern should be exported in CMYK or in ICC-profiled PDF formats, ensuring color integrity. File formats like PDF/X, TIFF, or high-resolution PNG help balance color accuracy with output reliability.

A consistent handoff process, from working file to final output, ensures that print teams, RIP setups, and finishing equipment see the artwork exactly as intended.

Preview Across Multiple Product Sizes

Patterns that look perfect on small merchandise can feel overwhelming, or underwhelming, on large surface areas. Previewing mockups of different dimensions helps designers refine scale, line weight, and visual distribution.

Many W2P systems make this immediate, allowing patterns to be visualized on mugs, boards, apparel, stationery, packaging, or signage without exporting separate manual output files. This not only improves customer experience but also reduces rework and proofing cycles.

How Custom Printing Businesses Can Profit from Repeating Pattern Designs

Repeating patterns offer Web-to-Print businesses a direct operational and commercial advantage. A single tile can result in dozens of sellable SKUs without the need to create separate design layouts for each product type.

This allows businesses to expand catalogs rapidly, launch seasonal collections faster, and introduce more niche product lines without additional design overhead. Customers, in turn, enjoy a more intuitive personalization experience. Instead of designing from scratch, they can apply a pattern instantly, adjust scale, see live previews, and complete their purchase in minutes.

For production teams, this design approach also supports automation. Once uploaded, the system applies the pattern across design surfaces, generates output files, and routes them to print without manual intervention.

Some enterprises even monetize the digital pattern design itself, selling digital pattern libraries, designer-uploaded artwork, or premium personalization packs. In every scenario, repeat patterns deliver the same outcome: higher efficiency, faster production, broader catalog depth, and increased revenue with less creative effort.

Wrapping It Up!Repeating pattern design is more than a creative technique; it’s a scalable business strategy for the modern custom print business. With the right workflow, easy-to-use pattern design software, and seamless tiling structure, a single design tile can efficiently power dozens of products without added design time.Customers gain the freedom to personalize patterns instantly, and printing teams benefit from automation, accuracy, and reduced proofing cycles. The result is a streamlined ordering journey and faster revenue growth from every pattern collection launched.If you want to adopt pattern-driven personalization, increase catalog depth, improve user experience, and differentiate your brand in an increasingly competitive print market, book a 1:1 live demo of our Web-to-Print solution for your print business today!

FAQ's

What is a repeating pattern in print?

Do repeat patterns work on all print products?

Can customers personalize repeating patterns in a Web-to-Print system?

How do Web-to-Print systems help prevent printing errors in patterns?

#1 Web to Print Software.

By submitting this form, you agree to our Privacy Policy